ELECTRICAL MANUFACTURING, EFFICIENT BENDING

(24/5/2023)

Sheet metal processing “bottleneck process”

Electrical cabinets are made of sheet metal and are used to protect the normal work of components. In the sheet metal processing process, the bending process is often regarded as a “bottleneck process” due to its complexity, which affects the whole process tempo, and the good or bad bending process also directly affects the final size and appearance of the product.

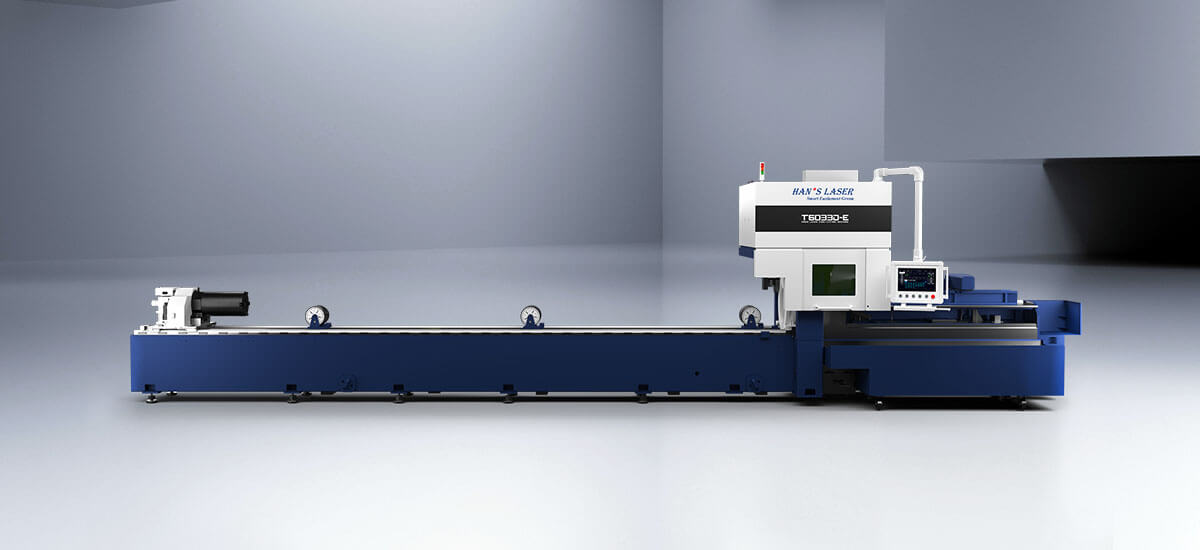

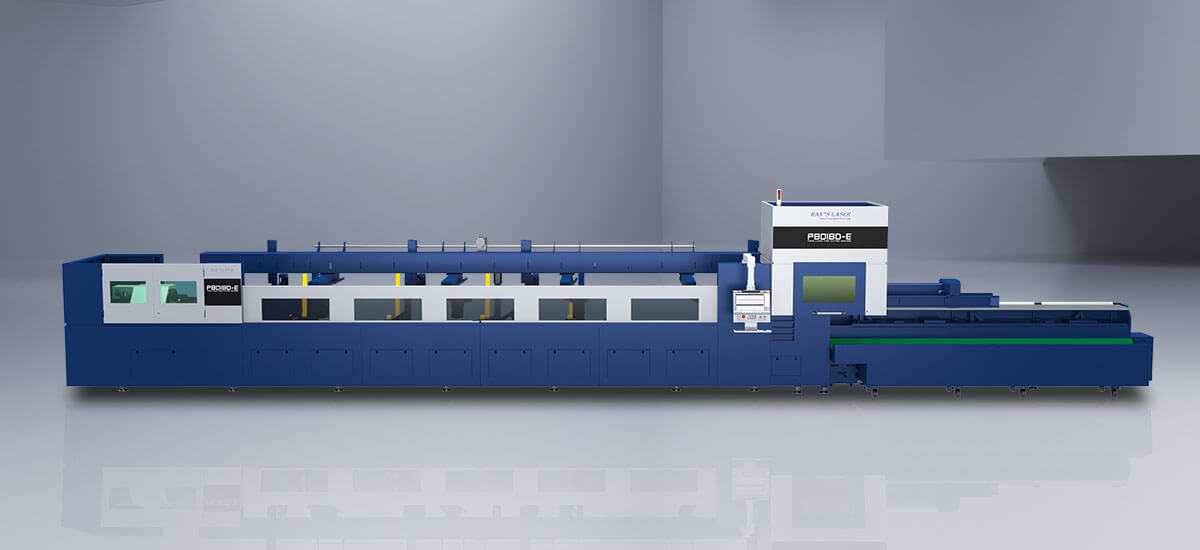

Han’s Laser Smart Equipment Group (HBS series of bending and forming equipment) can process various shapes of components with high efficiency and quality, helping electrical cabinet manufacturing to eliminate “bottlenecks”, improve quality and efficiency, and promote the transformation and upgrading of the electrical industry.

Efficient bending Intelligent precision

Some of the workpieces in the electrical cabinet sheet metal parts are larger in size, and the bending process is relatively complex, such as the side panels of the middle cabinet and panel-type workpieces. Da Clan HBS series bending machine is designed with larger closing height, throat depth and slider stroke, which expands the processing range and the use of tooling and can effectively meet the bending and forming of large and complex workpieces.

Han’s Laser HBS series bending machine is controlled by numerical control system, with the design of mechanical compensation, grating, high precision rear gear, high frequency control valve, etc., to further improve the bending accuracy, which can continuously make multiple bends for batches of workpieces, and can ensure the same batch of products with the same forming accuracy, to meet the demand for high precision batch processing of cabinet sheet metal parts in the electrical industry, and facilitate subsequent welding, painting and assembly.

Energy saving, green environmental protection

With the introduction of the “double carbon” goal, more carbon emissions will be transferred from the end-use energy industry to the power industry, and the pressure on carbon emission reduction in the power industry will continue to increase. The HBS series bending machine adopts a detachable and washable separate oil tank, which consumes less oil, can be moved and disassembled, and is convenient for cleaning and maintenance. It promotes carbon reduction, emission reduction, energy saving and consumption reduction in the production process, and helps electrical manufacturing to be energy-saving, environmentally friendly, and green.

According to the data of a Han’s Laser electrical cabinet user, the electricity consumption of ordinary bending machines is 6 kWh/hour, and the electricity consumption of Han’s HBS bending machines is 2 kWh/h. After using HBS bending machines, each equipment can save 10,000 yuan in electricity costs per year Diverse (3000 working hours/year, electricity fee 1.1 yuan/kWh).