Best-selling flagship at an affordable price!

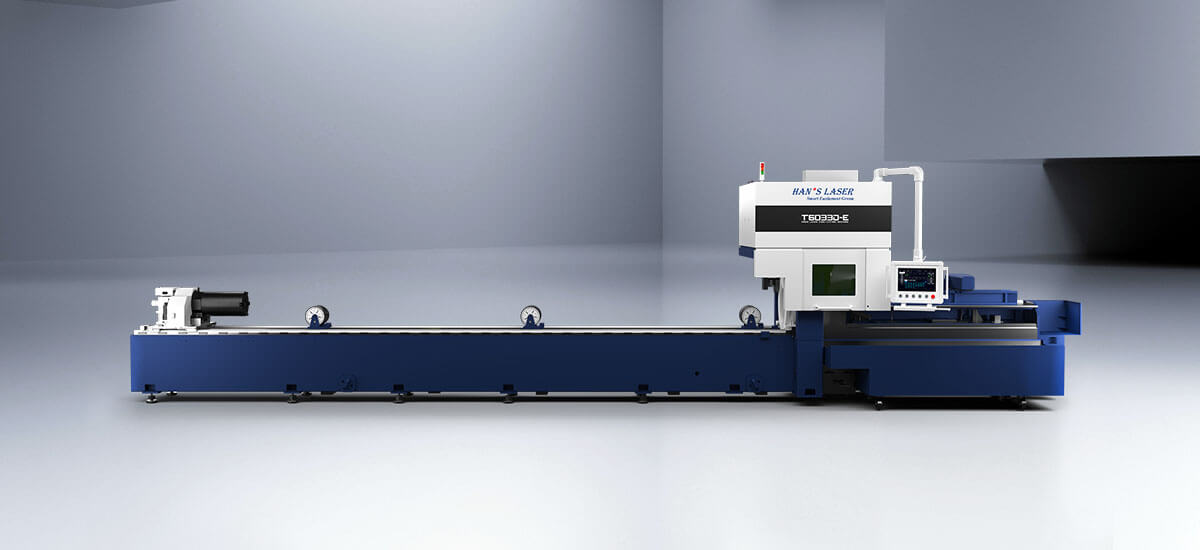

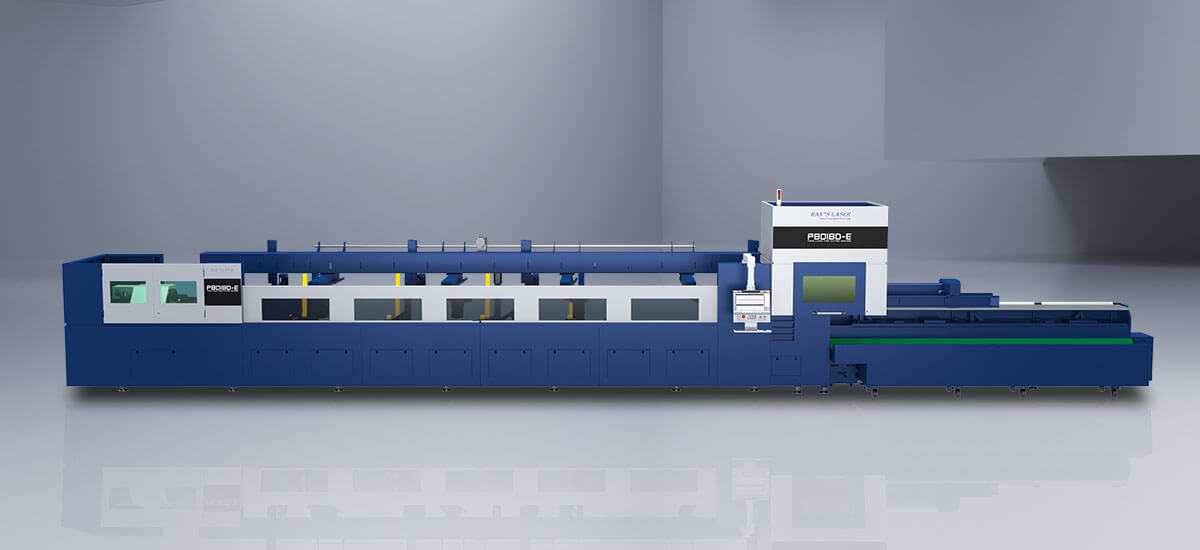

New DA series laser cutting

(18/4/2023)

Trusted by more than 1000+ customers.

Ideal solution for cutting metal medium and thick plates.

Brand-new Technology Blue Higher integration and higher cost performance

It can be used for cutting various metal materials such as medium and thick carbon steel, stainless steel, aluminum alloy, brass, red copper, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, copper alloy, manganese alloy, etc.

High stability and reliability, good processing effect, maintenance-free operation.

Power fluctuation within 100H is less than ±1%.

Internationally leading technology, reliable and stable

A new generation of laser cutting head independently developed by Han’s Laser

Easy to operate and highly recognized by the market.

The system is simple, convenient, and easy to use, with zero learning costs.

Multi-level perforation: support multi-level perforation, segmented or progressive arbitrary combination.

Good compatibility: support communication control of most mainstream lasers on the market.

Comprehensive functions: support basic processes such as flying cutting, leapfrog, compensation, lead-in line, micro-connection, pre-punching, film cutting, etc. Support capacitor edge finding, photoelectric edge finding, electric focusing, double exchange table, automatic layout, Advanced functions such as round pipe cutting, power-off memory QR code, line cutting, maintenance, etc.

Advanced technology: support cooling point, sharp corner ring cutting, release angle and other advanced technology support early opening and gas scouring. Support knife start, knife retraction, fine cutting process, support air movement obstacle avoidance, leapfrog intelligent judgment.

Convenient operation: support simple scheduling, virtual multi-station, scanning code map and other automated applications

Multi-Level Perforation

High-strength machine tool main bed

Excellent shock resistance, rigidity and stability.

Five-axis gantry precision machining master machine for one-time processing and forming.

Unique welding process: high-quality steel welding is used, and the unique welding process ensures structural rigidity while reducing welding stress.

Stress-relief annealing: Stress-relief annealing after welding, and secondary aging treatment after semi-finishing, effectively ensuring that the bed will not deform during long-term use, and has excellent shock resistance, rigidity and stability.

One-piece molding: The main bed adopts imported five-axis gantry precision machining master machine for one-time processing and molding to ensure the overall processing quality of the machine tool and the assembly accuracy of the whole machine. Double-sided dust extraction: Dust is extracted from both sides of the bed to remove the dust generated by cutting in time, which is clean and environmentally friendly.

Higher level of integration

Saves space and is easier to maintain

Lasers below 3000W can be built into the bed

Rich Configuration

A true value for money option

Multiple powers/multiple formats/multiple configurations, the whole system covers the market demand for single-table cutting

High cutting quality and good effect

Details decide the quality

It can perform high-precision and high-efficiency cutting of common metal flat plates with different thicknesses. The cutting section is smooth and tidy, without dross

Wide range of industry applications

Ideal alternative to traditional metal forming

It can perform high-precision and high-efficiency cutting of common metal flat plates with different thicknesses. The cutting section is smooth and tidy, without dross

Industry applications: rail transit, shipbuilding, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware and bathroom decoration advertising, laser external processing services And other machinery manufacturing and processing industries.